Temperature plays a crucial role in the performance of electric bus charging stations. At Luobinsen, we closely monitor how environmental factors, especially heat and cold, influence the efficiency of our pantograph charger systems. Understanding this relationship helps us ensure reliable and consistent power delivery for our clients’ fleets, particularly in regions with significant seasonal variations. Our experience shows that even small changes in temperature can affect charging speed, safety mechanisms, and long-term equipment durability.

How Temperature Affects Output

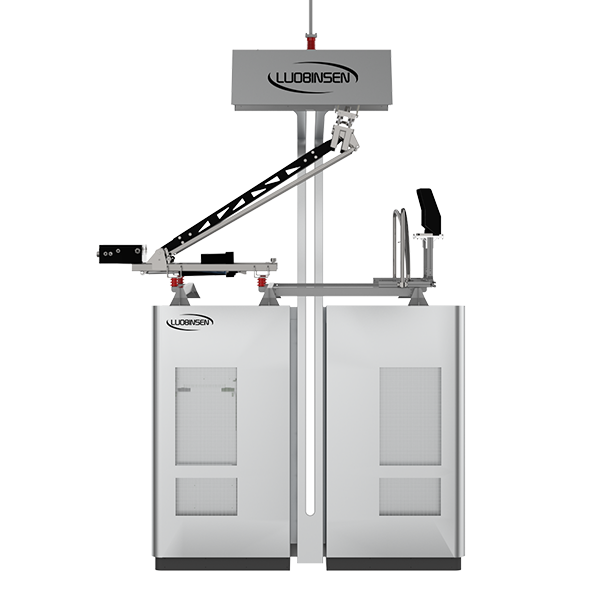

High temperatures can increase the resistance in conductive components, slightly reducing the charging current of a pantograph for electric bus. To address this, we integrate a constant temperature control system in our chargers, which maintains optimal operating conditions. Conversely, very low temperatures may impact the mechanical flexibility of the pantograph charger, delaying automatic lifting or affecting the efficiency of the conductive contacts. By employing PT1000 thermistors, our systems actively monitor temperature fluctuations and adjust performance parameters in real time, maintaining stable output under diverse conditions.

Advanced Safety and Material Considerations

Temperature variations also interact with safety features and materials. At Luobinsen, our pantograph for electric bus includes dual fire protection and a backup power system to safeguard operations in extreme weather. Critical components, including the conductive copper within the charging rack, are treated with a gold plating process to enhance conductivity and resist oxidation at high temperatures. Furthermore, using 316L stainless steel for structural elements ensures durability and minimal thermal expansion, keeping the charging alignment precise even when ambient conditions change. All major components come from internationally recognized brands, ensuring reliability and compliance with industrial standards.

Practical Benefits for Fleet Operators

By understanding the temperature impact on charging stations, we can offer solutions that maintain high efficiency while protecting the hardware. Our pantograph charger is designed for one-button automatic lifting, allowing operators to minimize manual intervention and avoid temperature-related mishandling. The integration of 15 safety protections ensures that fleets experience minimal downtime and reduced operational risk, even when outdoor temperatures vary drastically.

Conclusion

In conclusion, temperature has a direct effect on the performance of electric bus charging systems, influencing both output and operational safety. At Luobinsen, we prioritize designing pantograph for electric bus solutions that adapt to these environmental challenges. Through careful material selection, temperature monitoring, and integrated safety mechanisms, our systems ensure consistent, reliable, and efficient charging for commercial fleets. By considering these factors, fleet operators can optimize charging cycles while protecting the longevity of their investment.