At Luobinsen, we understand that maintaining a pantograph charger is essential for ensuring smooth operations of electric vehicle fleets. Regular maintenance not only prolongs the service life of the equipment but also helps avoid unexpected downtime that can disrupt operations. Our approach emphasizes preventive care combined with systematic checks, allowing us to identify and address potential issues early. For businesses relying on high-frequency charging, consistent upkeep of pantograph ev charging equipment is a practical investment in reliability.

Inspecting Core Components for Longevity

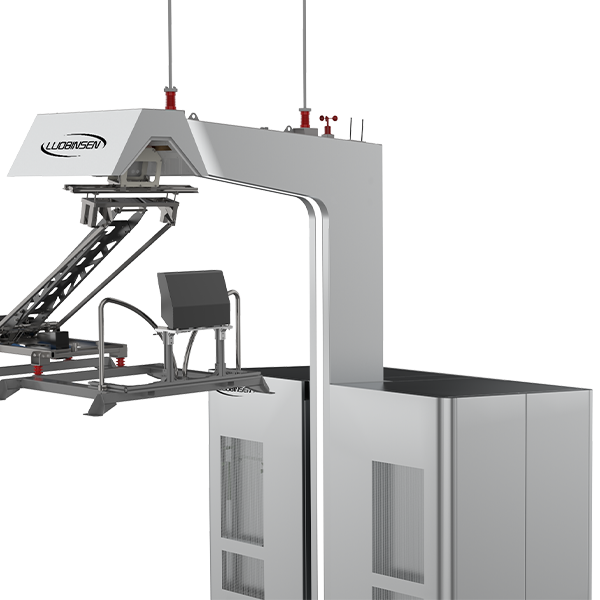

A critical part of maintaining a pantograph charger involves examining its key components. We pay special attention to the Upward Pantograph constructed from 316L stainless steel, ensuring that it remains free from corrosion or mechanical damage. The conductive copper in the charging rack, enhanced by a gold plating process, is carefully checked for debris or oxidation that could affect electrical contact. Temperature-sensitive elements like the PT1000 thermistor, alongside the dual fire protection system, are tested routinely to verify that they respond accurately under various conditions. Additionally, our constant temperature control system is monitored to confirm it maintains stable operation, safeguarding the charger during intensive usage.

Ensuring Safety and Backup Readiness

Safety is a priority in all our pantograph ev charging solutions. Our chargers include a backup power system that guarantees continuous operation even during power interruptions. The 15 safety protection mechanisms are regularly evaluated, including sensors, emergency stops, and circuit protection devices. By systematically verifying these features, we reduce risks and maintain compliance with industrial safety standards. This attention to detail ensures that every charging session remains secure for both operators and vehicles.

Streamlining Maintenance Procedures

We combine hands-on inspections with technology-assisted monitoring to keep our pantograph charger systems functioning optimally. The automatic lifting mechanism is checked for smooth operation using the one-button system, while moving parts are cleaned and lubricated to prevent wear. Components sourced from internationally recognized brands are monitored for performance indicators, enabling us to replace or service parts proactively. This structured approach minimizes unexpected failures and enhances operational efficiency for our clients’ fleets.

Conclusion

Proper maintenance of a modern pantograph charger is crucial for safe and reliable operations. At Luobinsen, we follow a systematic approach that addresses core components, safety systems, and mechanical reliability, ensuring that our pantograph ev charging solutions perform consistently. By combining quality materials, advanced technology, and routine inspections, we help businesses maintain uninterrupted charging services while protecting their investment. Regular care is more than maintenance—it is the foundation of dependable electric fleet operations.